IN-LINE CONTAMINATION MONITORS

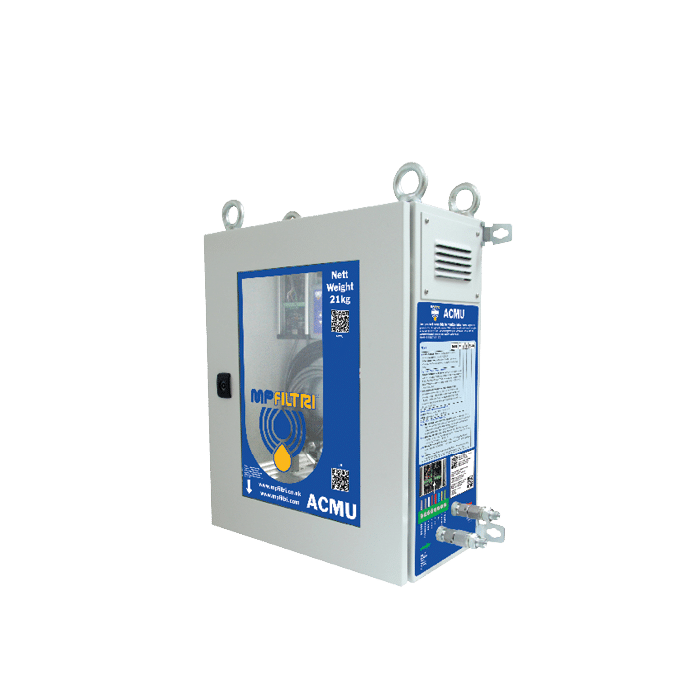

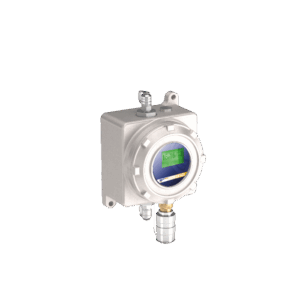

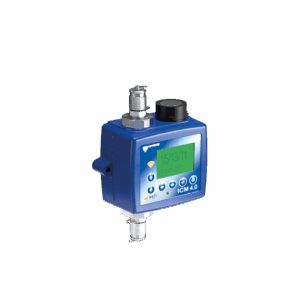

ACMU

Incorporating the ICM, hydraulic pump and valve circuit, the ACMU is specifically designed for viscous/ lubrication systems, where aeration is present.

-

Self priming particle counting via integrated pump and manifold design

-

Variants for non pressurised/ pressurised systems of lube oil/ gear box applications

-

Aeration suppression, that allows for improved contamination monitoring

-

Live real time monitoring

-

Specifically designed for wind/tidal/wave energy, gearbox applications, offshore & ship systems, lubrication & oil systems and test benches, it can be used with entrained air or turbulent flows, higher viscosity fluids and unpressurised systems

Applications

Industrial equipment

Download

ACMU

Catalog

PDF | 2.52 MB

ACMU

Manual

PDF | 7.38 MB

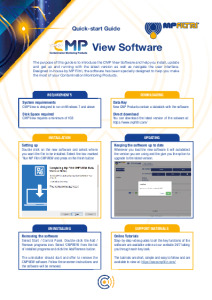

CMP-View SOFTWARE QUICK START GUIDE

Manual

PDF | 0.47 MB

CMP View_2.0.6

Software

EXE | 84.13 MB